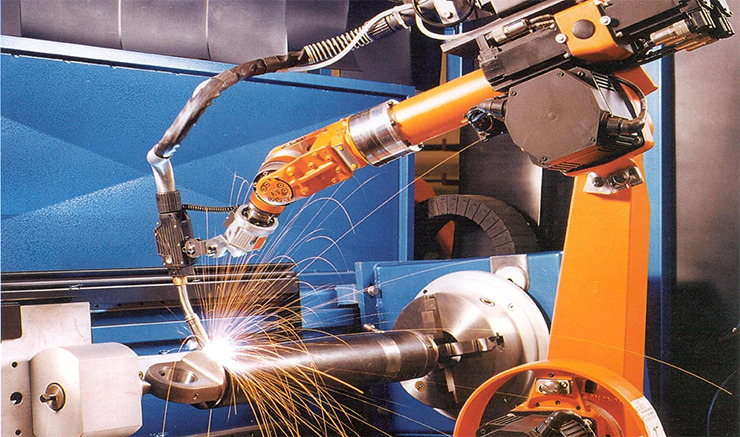

Lots of different companies use a welding process on a regular basis and as such, there are many different tools and pieces of equipment out there to choose from in order to help you to do the best possible job. There was a time when welding had to be done by a person but nowadays, as with many things, robotic systems can now do welding jobs more efficiently, affordably, quickly and accurately. You can invest in robotic welding systems to improve your business but how do you know which equipment to invest in?

Everyone seems to promise the latest technology when it comes to finding the best robotic welding systems and you will need to conduct your own research in order to ensure that you are buying a good quality product that you can rely on. You will need to make sure that all of your welding work is completed to the highest standard possible and this also applies when you invest in a robotic system to do the work for you. You can shop online for reliable welding equipment at affordable prices and you can choose to switch solely to robots or use a mixture of robots and humans on your welding production line.

Welding Trials

You should look to find a company that will allow you to do a welding trial, as this will give you the opportunity to test the equipment before you invest in it. You can also take this time to calculate how many robotic systems you will need in order to meet the demands of your ordersand finding the best solution for you can be better determined if you organise a trial period.

Benefits of Robotic Welding Systems

Here are a few of the reasons why using robotic equipment can be beneficial:

- It can save you time

- It can speed up the process

- It can help you to achieve a more reliable end product

- It can improve your delivery times

- It can increase the accuracy of your welding work

Robotic welding systems can also cut your labour costs, which is a huge appeal to modern business owners as robots never need to take time off work for holidays or sickness.

Automated Robotic Systems

Welding is a process that takes an exact skill and it can be hard to find humans who are trained in the art of welding. This is another reason why using automated systems is hugely popular and this type of modern equipment is generally used for the following two processes:

- Resistance spot welding

- Arc welding

You will need to do some online research to see what other people have to say about the equipment that you are thinking of investing in, as it is vital to ensure that it comes highly recommended before you make an investment.

Quality Technology

You will always need to ensure that you use modern welding equipment that boasts the latest technology, so take your time, do some research, ask people you know for advice and also contact a few providers to see which products they recommend.

Comments