The value of automation and robots in many manufacturing industries is growing. Industrial robots have transformed people in many industries. Robots beat humans in jobs that require precision, speed, endurance and reliability. Robots safely perform dirty and dangerous jobs. Traditional manufacturing robot programs include material handling (pick and set), assembling, painting, welding, packaging, palletizing, product inspection and testing. Industrial robots are employed in the diverse choice of industries including automotive, electronics, medical, food production, biotech, pharmaceutical and machinery.

The ISO concept of a modifying industrial robot is “an instantly controlled, reprogrammable, multipurpose manipulator”. In line with the definition it might be fixed in place or mobile for use in industrial automation programs. These industrial robots are prrr-rrrglable in 3 or even more axes. They are multi-functional products that might be custom-built and designed to do a quantity of methods.

The primary advantages of industrial robots is they may be made to match industry specific needs and could work continuously for any very long time, consistently meeting high manufacturing quality standards. The cost-effective existence duration of the commercial robot is roughly 12-16 years. Due to their persistent precision industrial robots are becoming an important part of manufacturing.

Industrial robots has taken care of into different groups based on their mechanical structure. The primary categories of commercial robots are:

Gantry (Cartesian) Robot: They are stationary robots getting three facets of motion. They work from an overhead energy power grid getting an oblong work envelope. They are mainly familiar with perform ‘pick and place’ actions. Gantry robots get their axes within the work causing them to be also perfect for shelling out programs.

SCARA Robots: (Selectively Compliant Articulated Robot Arm) These robots have 4 axes of motion. They move in a x-y-z matched up circular work envelope. They’re utilized for factory automation requiring pick and set work, application and hang up methods and handling machine tools.

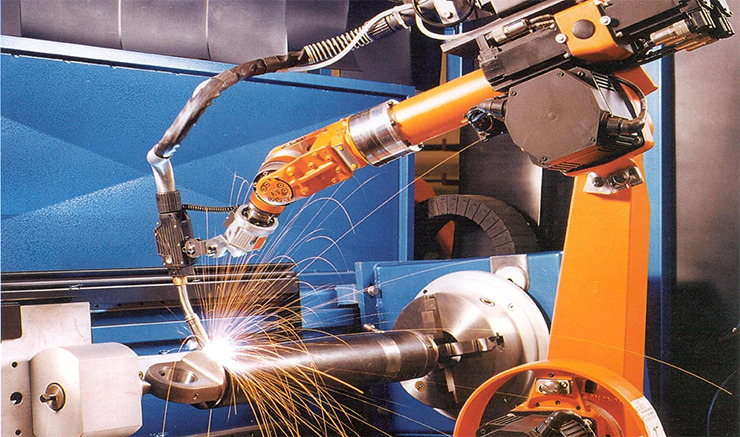

Articulated robots: An articulated robot has rotary joints. It might have from two to 10 or maybe more interactive joints. Articulated robots are very appropriate for welding, painting and hang up.

Fundamental industrial robot designs might be personalized with the aid of different add-ons. Finish effectors, optical systems, and motion remote controls are very important add-ons. Finish effectors will be the finish-of-arm-pedaling (EOAT) installed on robot arms. Grippers or wrenches that are employed to move or assemble parts are great good examples of finish effectors. Finish effectors are created and familiar with sense and talk to the outside atmosphere. The conclusion effectors’ design depends round the application needs in the specific industry. Machine Vision systems are robot optical systems. They are built-on digital input/output items and personal computers familiar with control other manufacturing equipment for instance robot arms. Machine vision may be used for your inspection of creation that for instance semiconductor chips. Motion remote controls are employed to move robots and position stages easily and precisely with sub-micron repeatability.

Industrial robots fill the requirement of greater precision, reliability, flexibility and production output inside the progressively competitive and complicated manufacturing industry atmosphere.

For More Information please visit My Lifestyle Blog

Comments