Computer Numeric Controlled automated machinery, commonly known as CNC machines, are considered among the on tops assets of companies of all sizes. Large manufacturing companies rely on them for operations of all types while even the small custom machining shops enjoy benefits of using CNC machines. The machines can even be appraised for collateral lending, family law, buy/sell agreements and even insurance purposes.

These machines are extremely versatile. The variable on the operation will vary majorly depending on the type of CNC machine you use. They are available in a wide range of sizes and types. Find a machining company specializing in CNC machining and order one that best meets your requirements.

Top Reasons to Invest in CNC Machines

As already emphasized, CNC machines are versatile and can deliver many benefits. One of the biggest reasons to rely on them is that there are no human errors. There are fewer mistakes and therefore, consistent machining is possible each and every time. The machining is precise and the production time speeds up.

As a number of mistakes are less, using Computer Numeric Controlled machines can reduce waste significantly. In addition, processes take less time and require minimum human involvement. Therefore, operator fatigue is reduced. Operators also find more time to perform other tasks which demand their attention. Even though the operators are expected to know how to run the software, in general, the skill level required operating machines is lower when companies have CNC machines.

Easy Switching Between Productions

Previously, setting a machine up for specific purpose took several days. This switching time between the production of different products can be saved by using CNC machines. It is as simple as loading a different software.

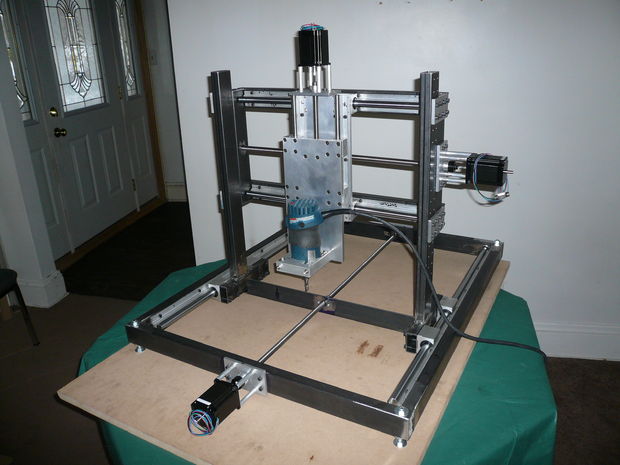

These machines are motion controlled, and they operate on different axes. The CNC lathe machine, for example, operates on the X and Y axis. The cuts are more delicate and precise when a machine operates on more axes. If you invest in a machine that operates many axes, you can show more creativity with your projects. This helps to offer better fabrication services.

The Computer Numeric Controlled machines are self-sufficient and can function without any serious human intervention. Operators are only required to use the computer software. Programming is written in a sentence such as structures that are in code. These codes instruct the different axes what to do.

There is no need of joysticks, handwheels, etc., and the new machining tools only require a good software. Operators can simply use the computer to instruct machines. Machines work tirelessly until guideline have been followed and the specifications are reached.

After the technical drawings are accepted, the materials are selected, the degree of precision and dimensions are determined, the programming software sends a digital data to the machining centers using special CNC digital technology.

You Can Choose a Company to Manufacture Your Projects

If you have a project in mind but do not want to invest in a Computer Numeric Controlled machine, there are companies that can perform the task for you. They can not only ensure quick production times but also offer many other benefits.

In such arrangements, you have the option of using the own material. They usually accept projects of all sizes, including oversized ones. You can not only produce, but also reduce and enlarge projects in multiple dimensions. Most of these companies do not have a minimum quantity. So, you can produce individually or in small batches.

Some of the specialized machinery also offer customized production and machining services with very high precision within a short period of time.

Comments